"Belt and Road Initiative" Sets New Height: Goodbond Contributes to Completion of Padma Bridge in Bangladesh

Release time:

2022-06-20

"Belt and Road Initiative", Reaching New Height

The successful completion of the Padma Bridge built by China in Bangladesh has once again refreshed the industry's perception of China's infrastructure capabilities. Connecting 21 districts in the southwestern part of Bangladesh with the capital Dhaka, the bridge reduces the originally three-hour river crossing time to just 10 minutes. This marks the end of a millennia-long history of ferrying for residents between these 21 districts in southern Bangladesh and the capital Dhaka. Preliminary estimates suggest that the bridge will contribute to around 1.5% annual GDP growth in Bangladesh, benefiting more than 80 million people.

1. Padma Bridge in Bangladesh

Located about 40 kilometers southwest of Dhaka, the Padma Bridge spans the Padma River and is known as the "Bridge of Dreams" by local residents. The bridge is a combined road and rail bridge with a main span of 6,150 meters, featuring a double-deck steel truss structure. The upper deck has four lanes for highway traffic, while the lower deck is for a single railway line. The Padma Bridge serves as a crucial transportation hub for the "Belt and Road Initiative" and is one of the important corridors for China and the Pan-Asia Railway.

The bridge is situated in the Ganges Delta region, where during the rainy season in Bangladesh, the river water is deep and wavy, with many ships navigating the construction waters, posing high safety risks and organizational challenges. For this project, the triangular oblique pile driving technique was used for the first time to drive multiple steel piles weighing 550 tons each into the riverbed. The largest bridge girder lifting vessel in Asia, "Tianyi No.1," was also utilized. Locally abundant flaky stone materials were selected for concrete production, and a new high-performance water-reducing agent was added to improve the strength and stability of the concrete.

2. Goodbond Contributes to Solving Bridge Challenges

The precast segmental assembly method refers to a bridge construction technique where the bridge is divided into several segments, prefabricated in a factory, and then transported to the bridge site for assembly, applying prestressing to form an integral bridge structure, commonly known as "beam splicing."

▲The picture shows "beam splicing"

The concrete and longitudinal steel bars at the splice joints of precast concrete bridge segments are disconnected, and the structural integrity strongly relies on the reliability of force transmission and connection structures at the splice joints, making the splice joints between segments potential weak points in the overall bridge structure. Therefore, the treatment of segment joints is crucial.

After rigorous review and testing by the Bangladeshi owner and supervisor, Goodbond's "Beam Splicing Adhesive" emerged victorious against foreign competitors due to its excellent cost-effectiveness and successfully participated in this historic project. Goodbond will continue to contribute to the high-quality development of Chinese national brands.

Goodbond's JN-P Precast Segmental Assembly Structural Joint Glue (Epoxy Adhesive for Precast Segmental Assembly), also known as Beam Splicing Adhesive, is an A-B two-component modified epoxy adhesive used for bonding mating surfaces in precast segmental assembly construction. It offers high strength, high bonding strength, high elastic modulus, waterproof and corrosion resistance, and minimal impact from construction climate conditions, serving as an important guarantee for rapid construction, long-term durability, and environmental friendliness of prefabricated bridges.

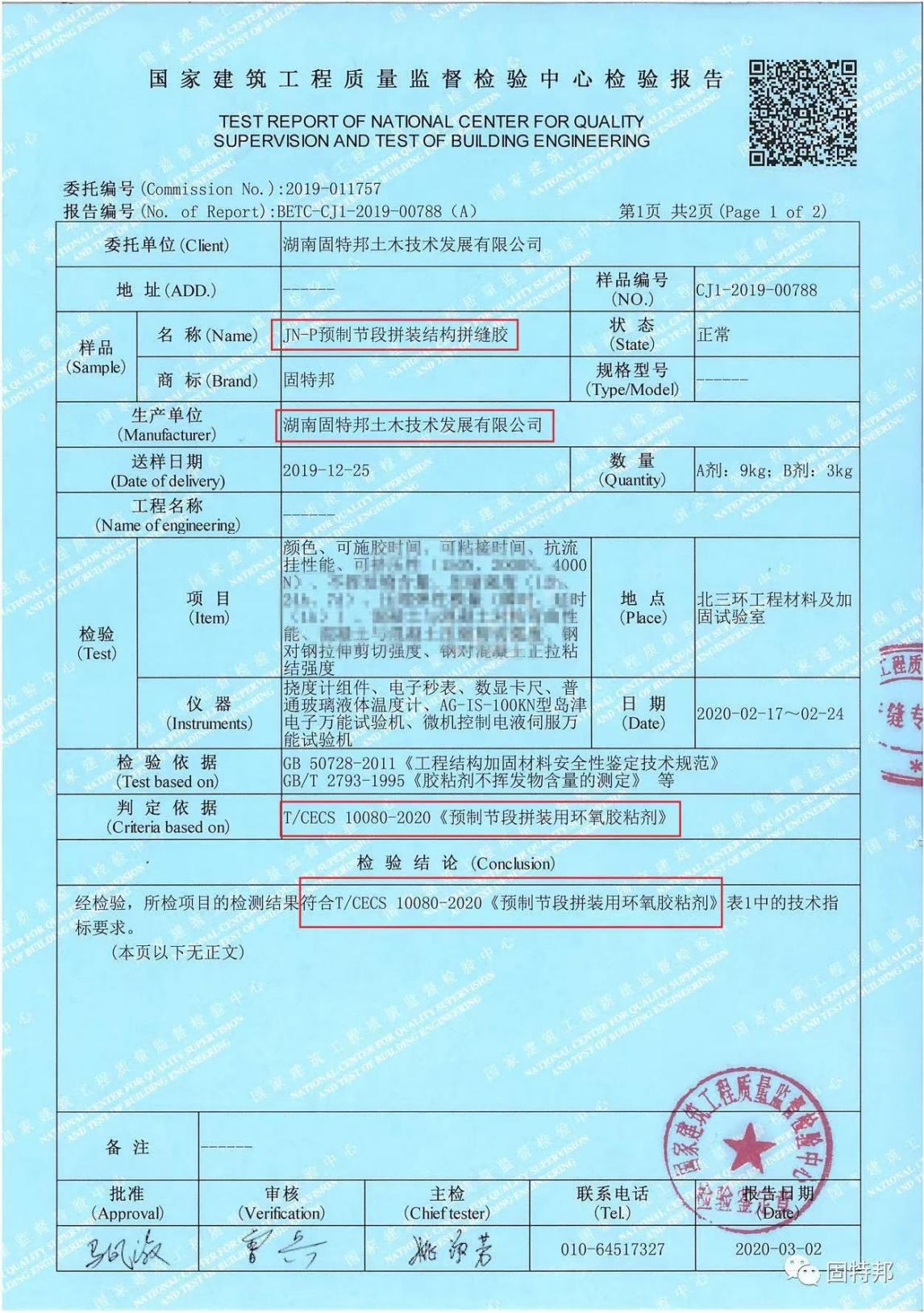

The standard "Epoxy Adhesive for Precast Segmental Assembly" (T/CECS 10080-2020), edited by Goodbond, was officially approved and implemented on March 1, 2020.

Goodbond's JN-P Precast Segmental Assembly Structural Joint Glue (Epoxy Adhesive for Precast Segmental Assembly, commonly known as "Beam Splicing Adhesive") has been tested by the National Construction Engineering Quality Supervision and Inspection Center according to the standard "Epoxy Adhesive for Precast Segmental Assembly" (T/CECS 10080-2020). The test results of the submitted items fully meet the standard technical requirements, and the test report has been issued, marking the first test report in China that complies with the new standard.

3. Technological Benchmark in the Bridge Sector

Goodbond has participated in the construction of bridges such as the Taohuayu Yellow River Bridge in Henan, the Dongting Bridge on the Hangzhou-Ruili Expressway, the Hong Kong-Zhuhai-Macao Bridge, Shishou Yangtze River Bridge in Hubei, Jiayu Yangtze River Bridge in Hubei, the Central and Wan Chai Bypass in Hong Kong, the Taipa section of the Macao Light Rail Transit, the Padma Bridge in Bangladesh (combined road and rail), and Chibi Yangtze River Bridge in Hubei. As a benchmark enterprise in China's special adhesive industry for civil engineering, Goodbond has been committed to high-quality development, building the core competitiveness of national brands!

Key words:

Next Page