Goodbond Assists in Successful Close of the World's Largest Span Steel-Concrete Composite Girder Cable-Stayed Bridge - Chibi Yangtze River Bridge

Release time:

2021-03-17

With the smooth rotation and connection of the last steel box girder into place, the Chibi Yangtze River Bridge in Hubei Province, assisted by Goodbond, has successfully achieved close!

The Chibi Yangtze River Bridge is an important part of Hubei Province's "Six Verticals, Five Horizontals, and One Ring" highway transportation network. It is also a key control project for the Tianmen-to-Chibi first-class highway crossing the Yangtze River. The total length of the route is 11.2 kilometers, with the Yangtze River Bridge spanning approximately 3.35 kilometers. The main towers are made of reinforced concrete, with the tower columns above the bridge deck in an "H" shape and the lower tower columns converging into a "diamond" shape.

The length of the main bridge is 1,380 meters , and the main span is 720 meters. The bridge has the world's largest span with double-tower, double-cable-plane, and double-sided steel-concrete composite girder cable-stayed bridge structure.

Goodbond Technology Solutions

Addressing the complex stress and susceptibility to cracking and water infiltration in the wet joints of bridge concrete structures, Goodbond has developed specific technical solutions tailored to the construction needs of the main bridge of the Chibi Yangtze River Bridge. These solutions aim to improve construction performance, crack resistance, and durability, thereby effectively controlling and enhancing the quality of wet joint concrete.

Goodbond has successfully developed and applied ettringite-based early-strength, low-shrinkage, and low-creep wet joint concrete formulation technology, construction techniques, and quality control measures in the wet joint concrete construction between the steel-precast concrete decks combined main beams of the main bridge of the Chibi Yangtze River Highway Bridge.

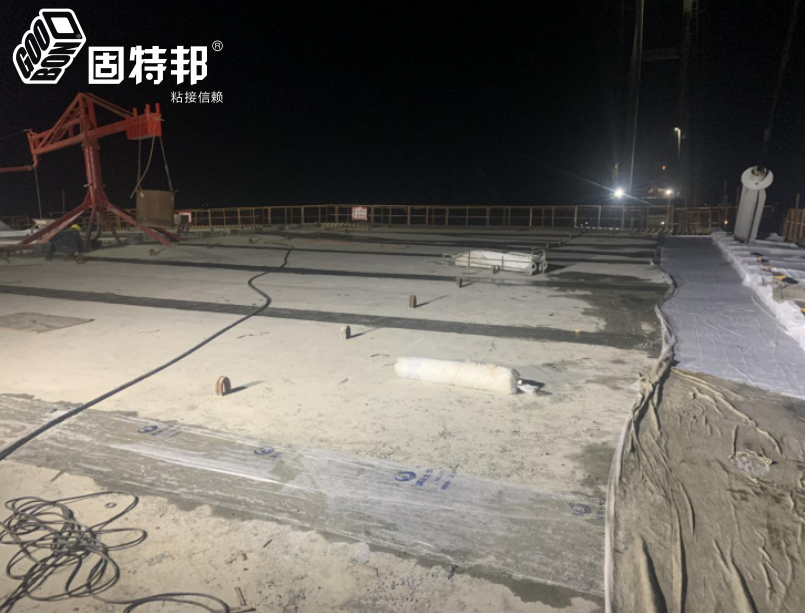

Experimental site of Goodbond technical team

The ettringite-based early-strength, low-shrinkage, and low-creep wet joint concrete is formulated by a composite admixture (GMA) innovatively developed by GOODBOND. It boasts the following characteristics:

Excellent mechanical properties, with 3-days compressive strength and elastic modulus reaching 90% of the design values.

Low shrinkage and creep properties, with a 20% to 30% reduction in shrinkage and creep when loaded at an early age compared to normal-age loading for ordinary concrete.

Outstanding interfacial bonding performance, with a 60% increase in interfacial bonding strength between the new and old concrete compared to ordinary concrete.

Excellent crack resistance, with no visible cracks during the construction process.

Good construction performance, with fluidity exceeding 550mm and no loss in slump spread after 2 hours.

Goodbond GMA Products

Chibi Yangtze River Bridge Application Scenarios

Actual photos of the Chibi Yangtze River Bridge using Goodbond GMA composite admixture

Goodbond’s Professor Peng personally went to the site to provide guidance

Based on the actual needs of the project, the Goodbond Chibi Yangtze River Bridge project team has developed ettringite-based early-strength, low-shrinkage, and low-creep wet joint concrete formulation technology, construction techniques, and quality control measures through systematic theoretical analysis, material research and development, and construction process control. These have provided solid scientific and technological supports for the successful construction of the Chibi Yangtze River Bridge and the improvement of bridge technology.

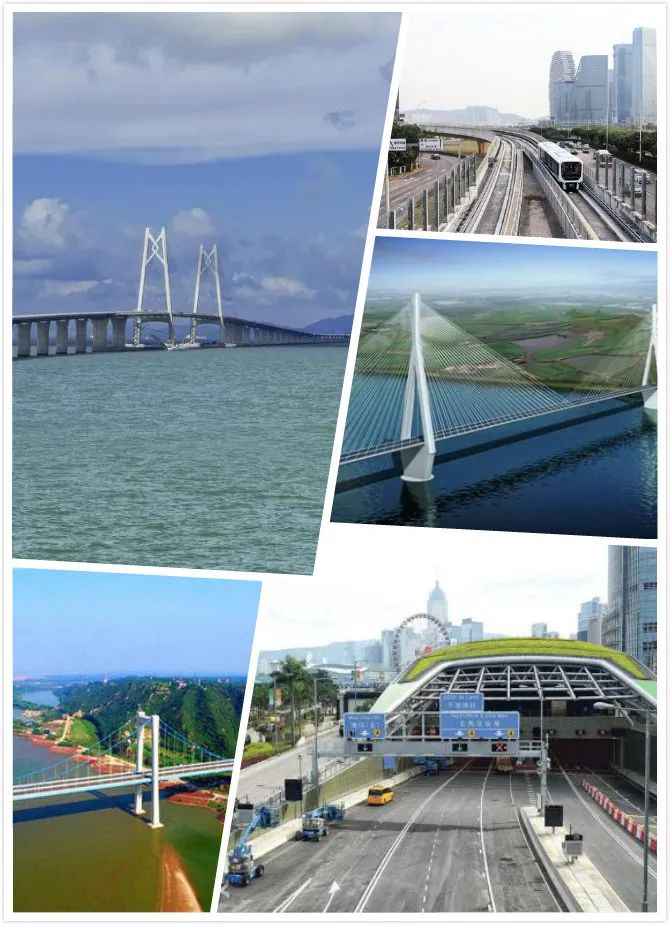

Other GMA Application Scenarios

GMA can be used in concrete structure reinforcement and retrofitting projects;

GMA can be used in concrete projects with dense reinforcement, complex shapes, and inconvenient vibration;

GMA can be used in special projects with high requirements for interfacial bonding strength between new and old concrete;

GMA can be used in frost-resistant, impermeable, and corrosion-resistant concrete projects;

GMA can be used in waterproof concrete, concrete-filled steel tube, and shrinkage-compensating concrete projects.

From the Hong Kong-Zhuhai-Macao Bridge to the Taohuayu Yellow River Bridge, as well as the Hong Kong Central-Wan Chai Bypass, the Macao Light Rail Taipa Section, Jiayu Yangtze River Bridge, Wuxue Yangtze River Bridge in Hubei, and now the Chibi Yangtze River Bridge, Goodbond, as a benchmark enterprise in China's civil engineering special bonding industry, has been committed to promoting high-quality national development and building the core competitiveness of national brands!

Goodbond now offers over 30 structural reinforcement products, more than 20 building decoration auxiliary materials, and over 10 high-speed railway maintenance products, covering three major categories of special bonding materials: modified epoxy adhesives, high-performance cement-based materials, and polymer-modified cement-based materials. These materials are suitable for more than 30 structural maintenance, reinforcement, waterproofing, and bonding techniques, some of which are unique to Goodbond. In addition, as one of the first enterprises in Hunan Province to obtain special professional engineering contracting qualifications, Goodbond has over 10 years of experience in structural reinforcement engineering construction and technical consulting services.

Key words:

Previous Page